Description

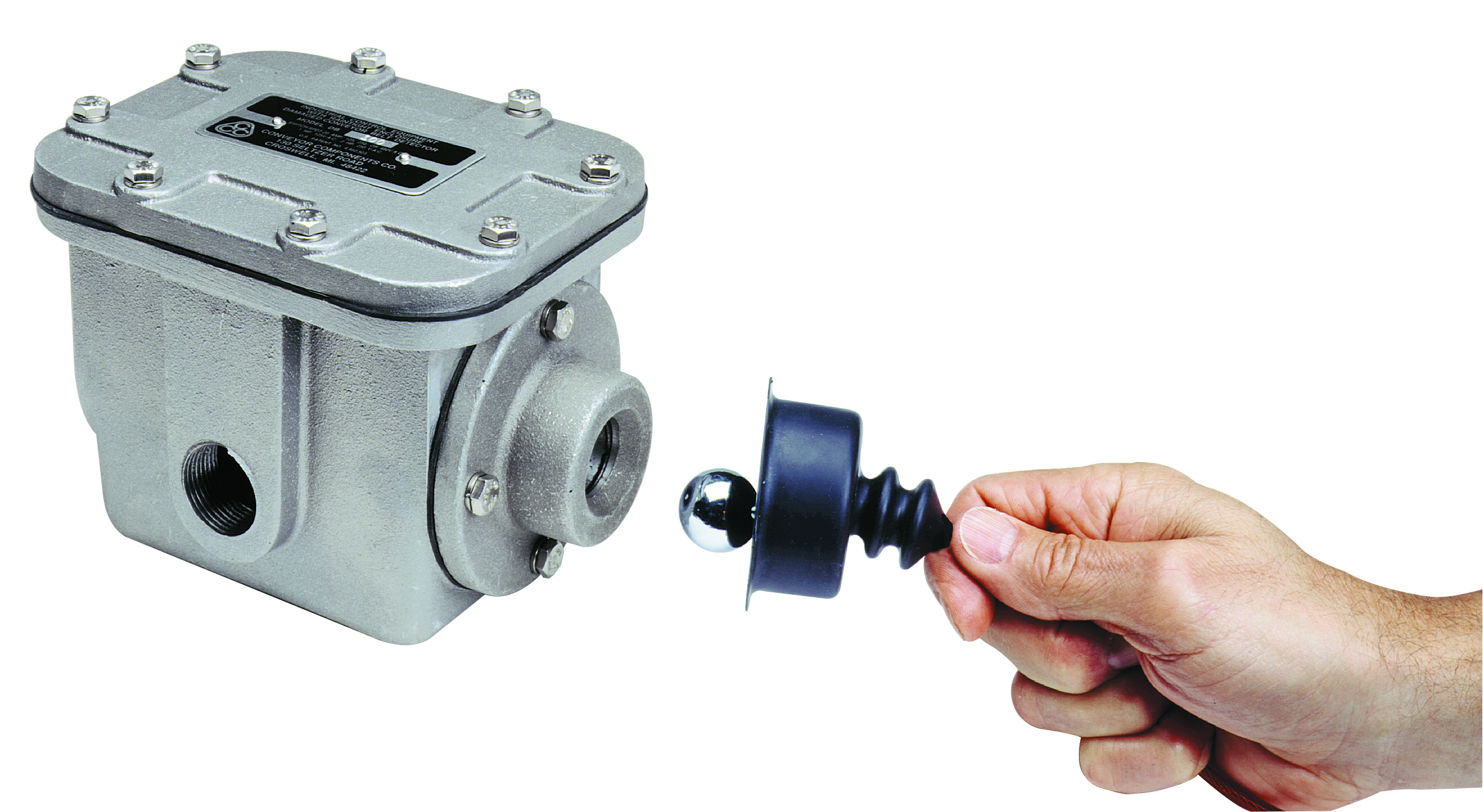

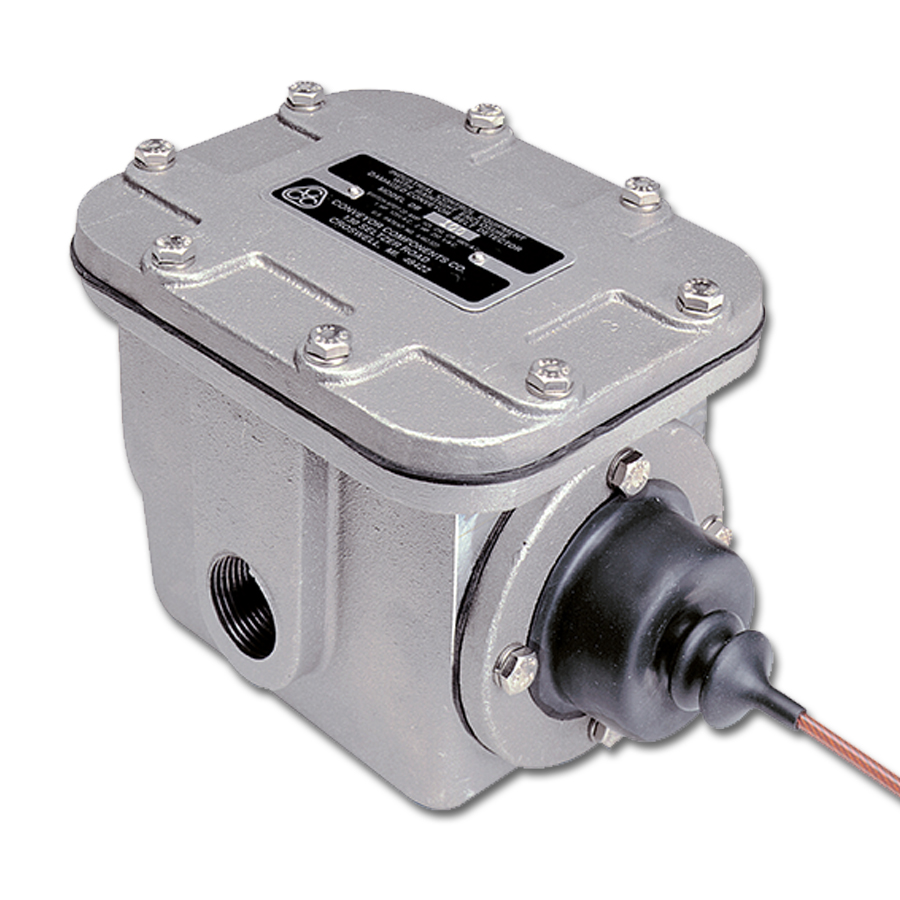

The Model DBX-100 is a cable-operated damaged belt detector that looks for punctures, tears, or protrusions through the conveyor belt and provides a means of an automatic shutdown to limit the amount of damage to the conveyor belt. The output contacts of the Model DBX-100 can control up to two separate circuits, one for machinery shutdown and one for an alarm.

The model DBX-100 provides substantial cost savings in replacement belting and downtime associated with belt splicing or replacement.

TECHNICAL SPECIFICATIONS:

- The housing is cast aluminum, rated NEMA Type 4/4X weatherproof and corrosion-resistant.

- The unit should be used in pairs for best protection of the conveyor belt.

- The unit is mounted on the conveyor by drilling (4) 13/32″ diameter holes.

- (2) 1″ NPT conduit openings.

- (2) dry, unpowered SP/DT microswitches rated for 20A @ 120 VAC, 240 VAC, and 480 VAC.

- Each unit is supplied with 10 feet of cable.

- Standard operating pull force is 4 lbs.

- Certified Maximum Ambient Temperature Rating: 40°C (104°F). Functional Ambient Temperature Rating: -40°C to 40°C (-40°F to 104°F)

- IP65 compliant.

- UL and c-UL (Canada) listed.

A portion of all sales goes to Operation Support Our Troops -America

A portion of all sales goes to Operation Support Our Troops -America

Reviews

There are no reviews yet.